For applications requiring a 100A drive current in electric tricycles, the TOLL package offers the following significant advantages:

1. High Power Density Advantages

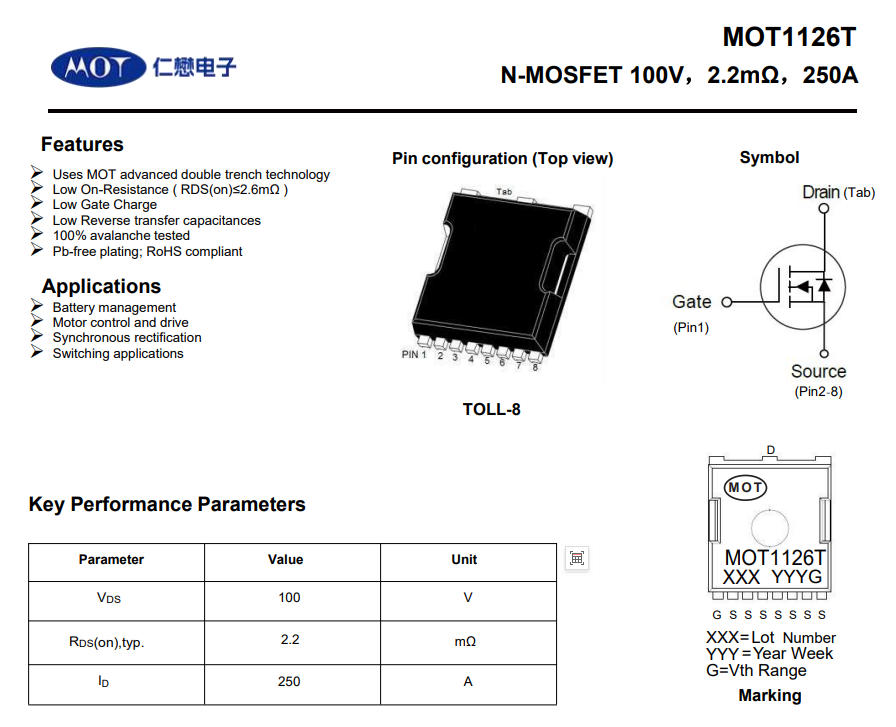

Significantly Reduced Size: The MOT1126T TOLL package measures only 9.90mm × 11.68mm × 2.3mm. Compared to the traditional D2PAK package, it reduces PCB board area by 30%, height by 50%, and saves 60% of board space. This compact design is particularly well-suited to the limited space requirements of electric tricycle controllers, allowing for the integration of more functional modules within the same space.

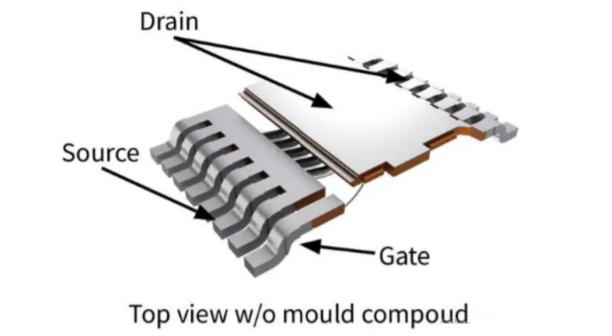

2. Superior Electrical Performance Low On-Resistance and Parasitic Inductance: The MOT1126T TOLL package features an advanced leadless design, with an on-resistance as low as 2.6mΩ and a parasitic inductance of only 2nH at 10V drive. This results in lower on-resistance and higher peak current capability, effectively reducing power loss under 100A drive current and improving system efficiency by more than 15%.

High current carrying capacity: The MOT1126T TOLL package can handle a maximum continuous current of over 250A, fully meeting the stringent requirement of 100A drive current while providing ample safety margin. Some models (such as the MOT113T) even support a continuous current of 400A, providing reliable protection for transient high-current scenarios such as acceleration and hill climbing of electric tricycles.

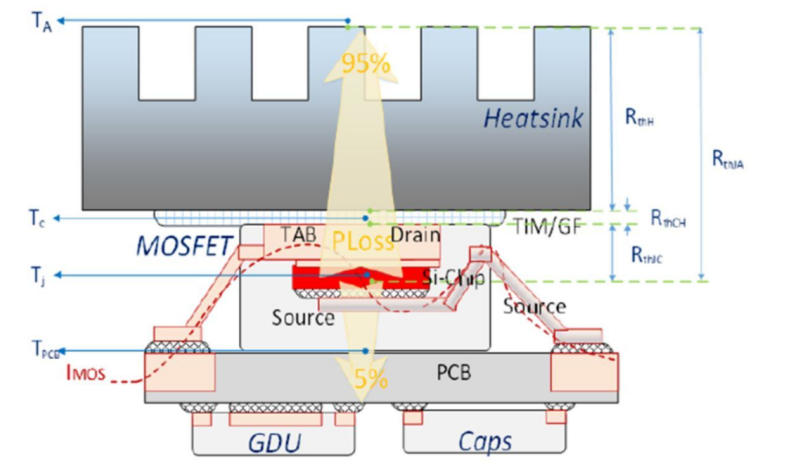

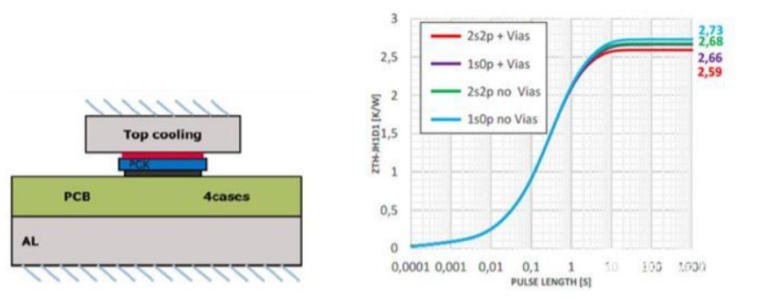

3, Excellent Heat Dissipation Performance

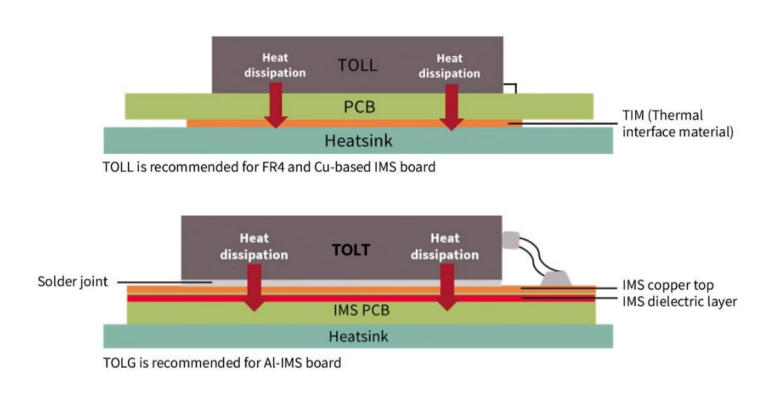

High-Efficiency Heat Dissipation Path: The heat dissipation path of the MOT1126T TOLL package is Junction→Case→Solder→PCB→VIAs→PCB→TIM→Heatsink. Although the path is relatively long, the heat dissipation efficiency is still very high. Compared to the traditional TO-247 package's thermal resistance of 2.5-3.0℃/W, the MOT1126T TOLL package's junction-to-PCB thermal resistance is only 1.2-1.5℃/W, representing an improvement in heat dissipation performance of approximately 39%. This is crucial for the high-temperature environment generated by the long-term operation of electric tricycles.

4, System Cost Optimization

Reduced Parallel Quantity: Since a single MOT1126T TOLL packaged device can carry over 100A of current, compared to traditional packages that require multiple devices in parallel, the number of devices can be significantly reduced, lowering BOM costs and PCB design complexity. At the same time, fewer parallel devices also mean lower drive circuit costs and simpler heat dissipation design.

5, High Reliability Guarantee: Automotive-Grade Certification: Inmark's TOLL packaged products have passed AEC-Q101 certification, with a maximum junction temperature of 175°C, supporting a wide operating temperature range of -40°C to 150°C. All devices undergo 100% avalanche and gate resistance testing to ensure long-term stable operation in harsh environments such as those caused by vibration and humidity in electric tricycles.

6, EMI Performance Optimization

Low Parasitic Inductance: The low parasitic inductance (<2nH) of the Renmao TOLL package effectively suppresses voltage overshoot and ringing during switching, reducing electromagnetic interference (EMI) and helping electric tricycles meet EMC certification requirements.

In summary, the TOLL package, with its high power density, low conduction loss, excellent heat dissipation, and automotive-grade reliability, is an ideal choice for 100A drive current applications in electric tricycles, significantly improving system efficiency, extending driving range, and reducing overall cost.

Headquarter: 19th Floor, SCTC Mansion, Guiyuan Rd, Luohu, Shenzhen, Guangdong

Headquarter: 19th Floor, SCTC Mansion, Guiyuan Rd, Luohu, Shenzhen, Guangdong Contact Phone:+86-755-82527851

Contact Phone:+86-755-82527851