A typical lithium-ion battery cell has a rated voltage of 3.6V (ternary) and 3.2V (lithium iron ), a maximum charging termination voltage of 4.2V (ternary) and 3.6-3.8V (lithium iron), and a minimum discharge termination voltage of 2.5V. High discharge (< 2.5V) can lead to irreversible damage, such as capacity loss and increased self-discharge. Over-voltage (> 4.2V for ternary) (> 3.8V for lithium iron) can cause spontaneous combustion, posing a safety hazard. A Battery Management System (BMS) monitors cell voltage, temperature, and discharge current in real time for battery packs with different series and parallel configurations, so as to improve the safety and lifespan of battery pack .

The main reasons why lithium batteries require protection boards include the following:

*Over-charge Protection: The protection board monitors the battery's charging status and automatically cuts off the charging circuit when the battery is fully charged, to prevent damage from overcharging.

*Over-Discharge Protection: During battery discharge, the protection board monitors the battery voltage and automatically cuts off the discharge circuit when the voltage falls below a set value, to prevent damage from over-discharge.

*Over-current Protection: The protection board monitors the battery current and automatically cuts off the current when it exceeds a set value, to prevent damage from excessive current.

*Short-Circuit Protection: The protection board monitors for short circuits and automatically cuts off the circuit when a short circuit is detected, to prevent damage from short circuits.

*Temperature Protection: The protection board monitors the battery temperature and automatically cuts off the circuit when the temperature is too high or too low, to prevent damage from abnormal temperature.

*Balancing Function: The protection board balances the voltage of each battery in the battery pack, to ensure the overall performance of the battery pack.

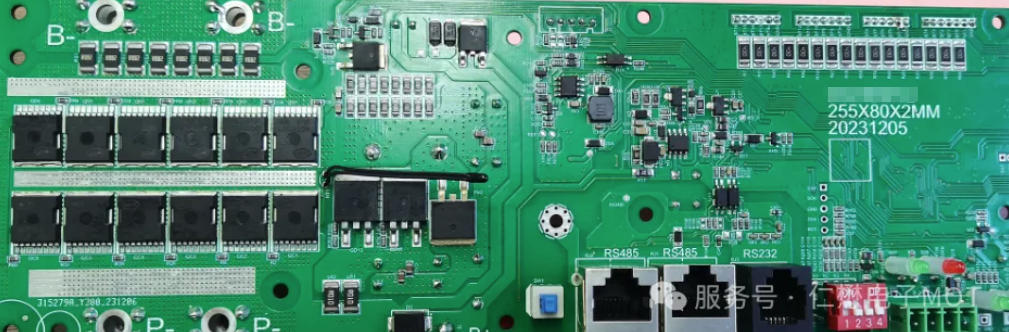

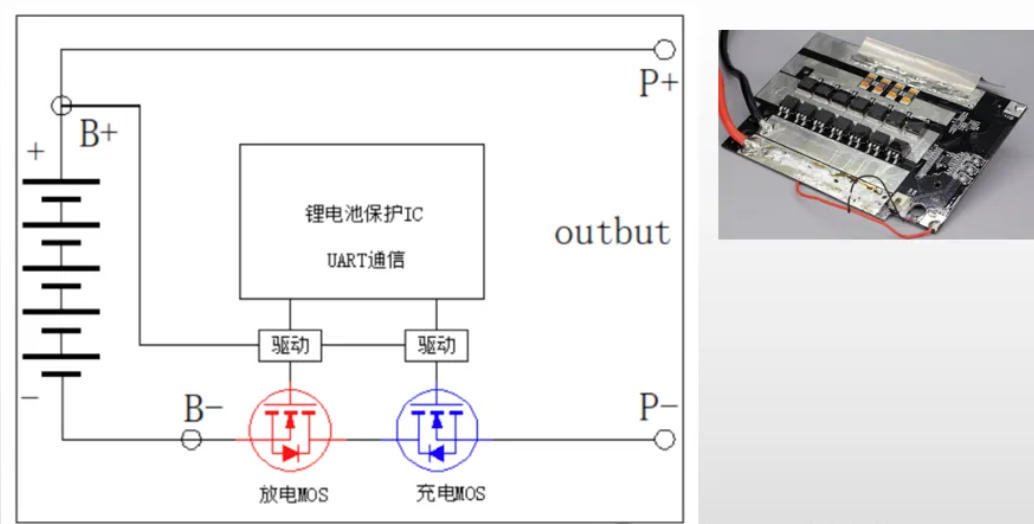

BMS Protection board diagram:

Recommended MOSFET selection for BMS protection board (Package and internal resistance are not limited. Customer can choose according to their needs).

|

Battery System |

Power range |

Illustration |

Characteristics and recommendations |

|

12V Battery |

200-500W |

Ternary in 3 series Lithium iron in 4 series |

30V-40V N-ch Mosfet MOT4383T MOT4550T |

|

24V Battery |

500-1000W |

Ternary in 6 series Lithium iron in 7 series |

40V-60V N-ch Mosfet MOT6111T MOT6556T |

|

36V Battery |

1000-1200W |

Ternary in 10 series Lithium iron in 12 series |

60V-75V N-ch Mosfet MOT6111T MOT6556T |

|

48V Battery |

1200-2000W |

Ternary in 13 series Lithium iron in 15 series |

80V-85V N-ch Mosfet MOT8576T MOT8112T |

|

60V Battery |

2000-2500W |

Ternary in 16 series Lithium iron in 18 series |

90V-100V N-ch Mosfet MOT1120T MOT1115T |

|

72V Battery |

2500-3000W |

Ternary in 20 series Lithium iron in 23 series |

110-120VNMOS MOT1121T MOT5130T |

Lithium-ion battery protection boards play a crucial role in ensuring the safety using of battery and extending its lifespan. With the rapid development of the new energy market and continuous technological innovation, the applications of lithium-ion battery protection boards are very broad.

Headquarter: 19th Floor, SCTC Mansion, Guiyuan Rd, Luohu, Shenzhen, Guangdong

Headquarter: 19th Floor, SCTC Mansion, Guiyuan Rd, Luohu, Shenzhen, Guangdong Contact Phone:+86-755-82527851

Contact Phone:+86-755-82527851